You might also be interested in

Not the right one?

E-Mail info@dietzel-hydraulik.de, Tel.: +49 36602 140-0

Reliable machine components of the highest quality are an important prerequisite, especially in the agricultural machinery industry. Agricultural machinery manufacturers such as KRONE therefore pay particular attention to high quality criteria for supplier products when selecting their suppliers. Customized hydraulic solutions are required for the drive and working hydraulics of agricultural machinery in particular, in order to make optimum use of the installation space of the machines.

KRONE approached Dietzel Hydraulik within the scope of a project already realized several years ago - the plastic tanks used for the hydraulic oil of the forage harvester series BIG X and mower conditioner series BIG M, were to be "hosed". Special challenge - the Quick Connect plastic fittings developed by Argo Hytos were to be attached to the hose with metal sockets instead of the originally planned clamp solution. A special requirement for Dietzel Hydraulik, which was of course implemented according to the customer's wishes - the work was carried out according to the Dietzel principle.

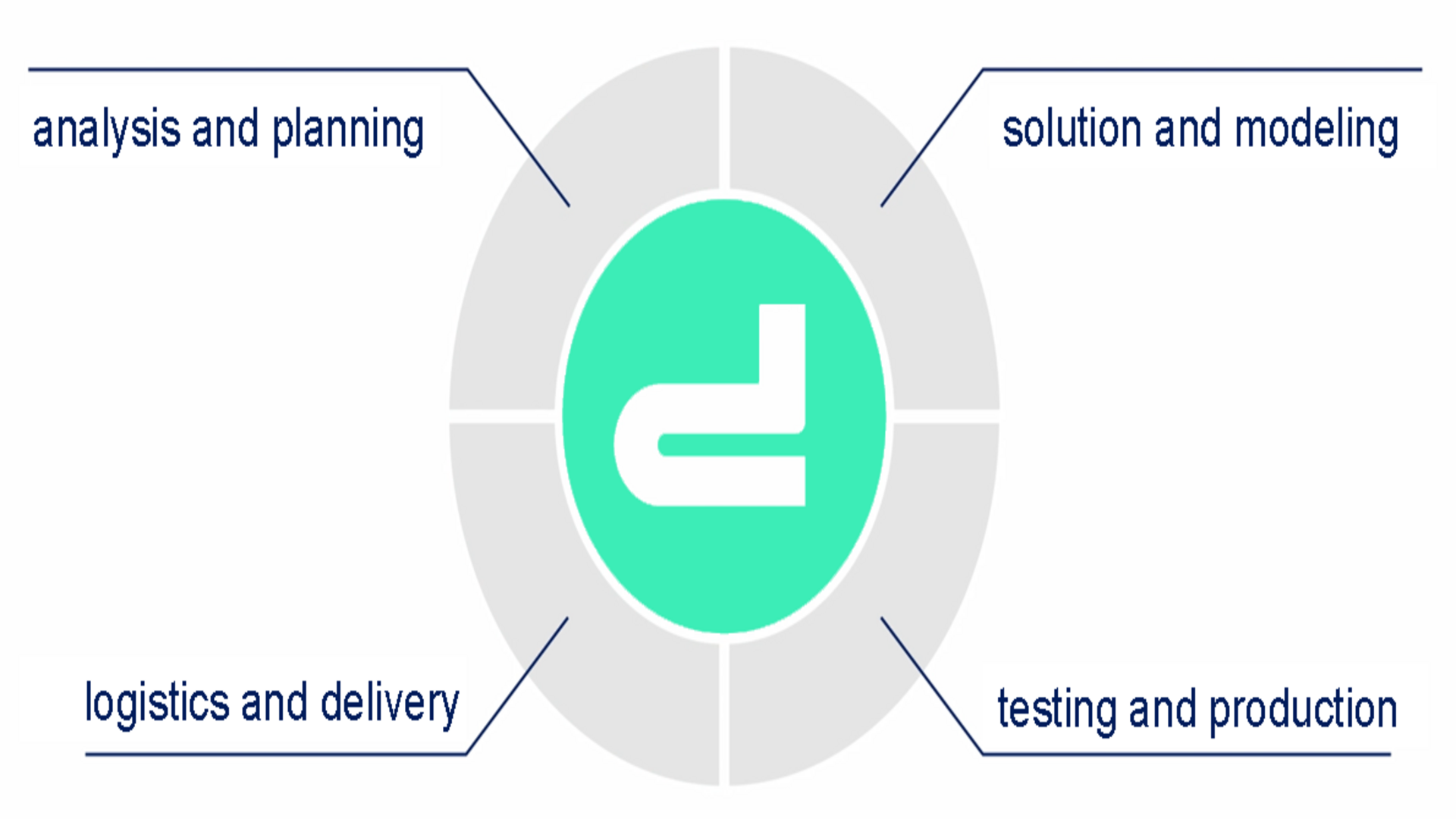

In hydraulics, oil flows from A to B. The way in between is Dietzel. Dietzel brings a hydraulic solution to production readiness quickly and cost-effectively, perfectly tailored to the customer's requirements. To put this into practice, Dietzel Hydraulik works according to the so-called Dietzel principle. First, the customer's requirements are recorded and analyzed before initial solutions are modeled. Extensive tests are carried out before series production begins. This is followed by delivery of the products adapted to the customer's requirements.

In the described project with KRONE, the requirements submitted to Dietzel Hydraulik were first analyzed and evaluated. Corresponding samples of the plastic valves were provided by KRONE. Based on these, the Dietzel engineers and technicians developed proposed solutions. In contrast to metallic valves, the plastic valves supplied were not standardized. Therefore, a press parameter had to be defined for each nominal diameter and each connection. All developed fittings were tested at Dietzel according to the available testing possibilities and corresponding test reports were prepared. After final field tests at Krone, the first series was delivered. In the meantime, the Quick Connect fittings with metallic sockets have become established at KRONE, where they have become the standard for use with plastic tanks. "I was particularly surprised by the rapid development of the solution - from the first transmission of the requirements to Dietzel Hydraulik to the first samples, things progressed very quickly," says Thomas Snaadt, responsible for the hydraulic self-propelled technology division at KRONE.

What are the advantages of this unique connection technology? Since the hose assemblies are delivered to KRONE already pressed, the installation effort is reduced because no additional clamps have to be mounted. In addition, the operational safety is increased, because a higher tightness is guaranteed compared to a manually attached clamp solution. Furthermore, a better cleanliness of the hoses is possible, because at Dietzel all hose lines are cleaned with projectiles before crimping and closed after crimping, so that no impurities can get into the inside of the hose during delivery and storage.

In addition, Dietzel Hydraulik uses a so-called staking tool before crimping the hose line - which ensures that when the fitting is inserted into the hose, the socket also reaches behind the nipple. This setting tool was specially developed for KRONE for each type of fitting and each nominal size. Its use has been included as a work step in the work instructions. This ensures that every hose line leaves the Dietzel plant with 100% quality.

In terms of costs, this results in lower warehousing costs for KRONE, as well as lower costs for incoming goods inspection and picking processes, since only one item has to be stored or picked at a time instead of several. Not to be forgotten are the assembly costs. The hose assemblies, which are supplied already crimped, make assembly much easier and faster.

Dietzel Hydraulik specializes in developing individual hydraulic solutions for its customers. In this context, the company's in-house manufacturing competencies enable maximum flexibility and reliability. Dietzel covers a broad portfolio from machining to further processing, such as welding, soldering, bending, and even its own hose assembly. Quality is always the focus of the various production steps and work is carried out according to the Dietzel principle.